FRP Grating

SSF FRP & GRP Fiberglass Moulded Gratings Manufacturers

Shree Sabari Fibres (SSF) is among leading FRP/GRP Moulded Gratings Manufacturers in India well known in the industry for giving corrosion resistant, high strength, safe and durable Fiberglass moulded gratings to its esteemed clients in South India. Manufactured using ultra grade resin systems, out Fiberglass moulded gratings are especially designed to give optimum performance without compromising on international quality standards. SSF Fiberglass moulded gratings are light in weight and can be quickly fabricated and installed. Clients can avail FRP/GRP Moulded Gratings with us at industry leading prices. FRP/GRP

Moulded Gratings have low installation and maintenance costs as compared to steel. They are non-resistant to chemicals and UV stabilized assuring best action as compared to conventional metals especially wood.

Advantages of our FRP platform gratings:

- Slip Resistant

- Anti Corrision

- Chemical Resistant

- No Maintenance

- Economical

Besides available FRP/GRP Moulded Gratings, we do also offer customized Fiberglass moulded gratings to our clients on special request. You just have to explain your requirements to us and we are ready with cutting edge industrial solutions to help you. To know more on to our FRP/GRP Moulded Gratings and customized solutions, stay tuned with us.

| Product Code | Height (MM) | Mesh Size (MM) | Rib Thickness (MM) | Open Area (%) | Sheet Size (MM) |

|---|---|---|---|---|---|

| SM 25 X (38 X 38) | 25 | 38 X 38 | 7-5 | 69 | 3660 X 1220 |

| SM 38 X (38 X 38) | 38 | 38 X 38 | 7-5 | 68 | 3660 X 1220 |

| MM 30 X (20 X 20) | 30 | 38 x 38 | 7-5 | 63 | 3660 X 1220 |

| SM 50 X (50 X 50) | 50 | 50 X 50 | 8-5 | 71 | 3660 X 1220 |

For Customised Size and loading standards please contact us.

Products Application

- Pultruded Products

- FRP/GRP Gratings

- Light Poles & Utility Poles

- Cooling Tower Solutions

- FRP Epoxy Pultruded Profiles

- FRP Trefoil Clamps

- FRP/GRP Tanks

- FRP/GRP Luminaries

- FRP/GRP Canopies

Comparison with conventional materials

| PARAMETERS | SSF FRP GRATINGS | HOT DIP GI | SS |

|---|---|---|---|

| LIFE SPAN | High | Moderate | High |

| STRENGTH TO WEIGHT RATIO | High | Low | Low |

| LIFE CYCLE COST | Low | High | High |

| CORROSION RESISTIVITY | Very High | High | Moderate |

| CHEMICAL RESISTIVITY | High | High | Moderate |

| ELECTRICAL CONDUCTIVITY | Low | High | High |

| EMI / RFI TRANSPARENCY | High | Nil | Nil |

| INSTALLATION COST | Low | Moderate | Moderate |

| HANDLING | Very Easy | Difficult | Difficult |

| ANTI SKID | Available | NA | NA |

| COLOUR RANGE | Available | NA | NA |

Construction

FRP/GRP Gratings are manufactured by wet moulding and hot curing in a heated mould. The

reinforcement consists of continuous fibreglass roving in alternating layers, so the loads are

distributed evenly in all directions. Regularly Moulded GRP Gratings have a polyester resin

matrix. Glass content is approximately 35%. Standard colours are green, yellow or grey;

other colours are available according to RAL.

Accessories

Applicable for our manufactured FRP/GRP gratings, we have special support angles which are concreted into the basement directly.

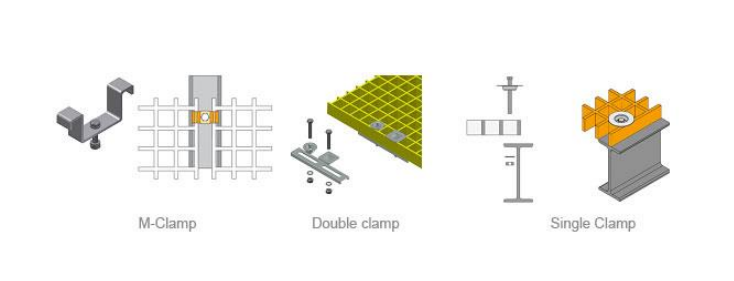

Fixing Sets

Easy to assemble without any special tools. A pultruded GRP angle mm can be used as a frame for all GRP gratings. Stainless steel fixing sets can be used for all standard GRP gratings and support constructions. To prevent GRP gratings perfectly against lifting and sliding away each panel should be fixed on at least four points.

Resin Selection

The first step to ensure Maintenance free flooring solution is SSF FRP Grating. Having an appropriate resin makes highest performance in the most demanding circumstances. SSF FRP Gratings are available in four standard resin grades which are highly economical while they maintain standard of performance.

| Resin Type | Resin Base | Description | Flame spread rating ASTM E84 |

|---|---|---|---|

| Type IFR | Isopthalic Polyester | Industrial Grade Corrosion resistance & fire retardant | Class 1, 25 or less |

| Type I | Isopthalic Polyester | Industrial Grade Corrosion resistance in acidic environment | Non fire retardant |

| Type V | Vinyl Ester | Superior Corrosion resistance & fire retardant | Class 1, 25 or less |

| Type P | Phenolic | Low smoke and superior fire retardant | Class 1, 5 or less |